Valvelink is proud to present its premier line of ISEN-UHC series Bypass Level Gauges, engineered for robust and reliable liquid level measurement across a wide array of industrial applications. Also known as Magnetic Level Indicators, these gauges provide a safe, clear, and accurate visual indication of liquid levels without the need for a direct line of sight into the tank, making them an ideal solution for challenging process environments.

The core of the Bypass Level Gauge’s design is a bypass chamber connected to the side or top of a vessel. This chamber houses a float containing a powerful permanent magnet. As the liquid level in the tank rises or falls, the float moves accordingly. The magnetic field from the float then acts upon an externally mounted indicator, providing a real-time, non-contact representation of the liquid level. This innovative design eliminates the common issues of leakage and breakage associated with traditional gauge glasses.

Principle of Operation

The visual indicator on the Bypass Level Gauge consists of a series of magnetic rollers or flaps, typically colored red/white or yellow/black. As the internal magnet within the float passes up or down the chamber, its magnetic field causes these rollers to rotate 180 degrees. This rotation flips the color of the rollers, with a rising level changing them from white to red and a falling level from red to white. This provides an immediate and easy-to-read visual indication of the liquid level, visible even from a distance. For enhanced visibility in low-light conditions, an LED indicator option is also available.

Versatility and Customization for Every Need

Valvelink’s ISEN-UHC series of Bypass Level Gauges are not a one-size-fits-all solution. They are designed for versatility and can be customized to meet the specific requirements of your process.

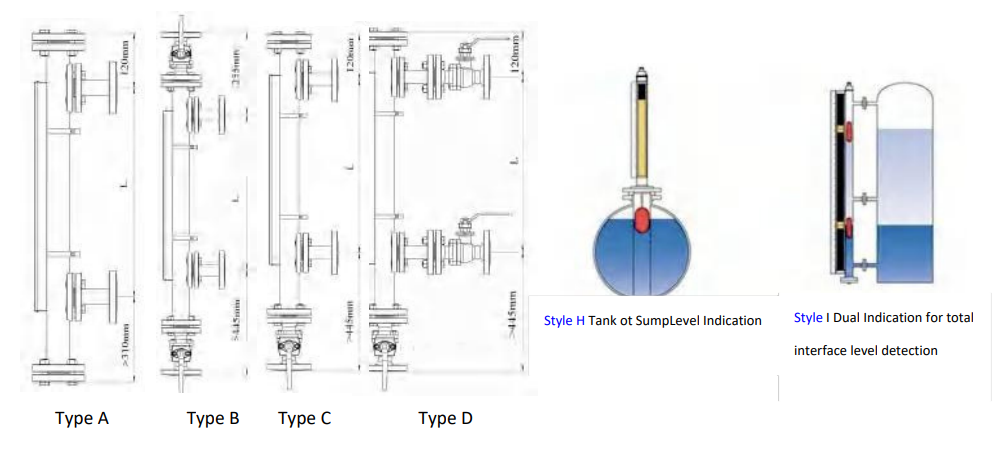

Mounting and Configuration:

- Side and Top Mounting: The gauges can be configured for either side mounting or top mounting on a vessel to suit various tank designs.

- Extensive Measurement Range: Standard side-mounted models offer a broad measurement range from 100mm up to 15,000mm, while top-mounted versions are available in ranges from 500mm to 3000mm.

Material Construction:

To ensure compatibility with a wide variety of fluids and operating conditions, Valvelink offers an extensive selection of materials:

- Metals: Options include SS304, SS316L, and SS321 stainless steel.

- Plastics: For corrosive environments, the gauges can be constructed from PP (Polypropylene), PVC, and PVDF.

- Lined Options: For highly aggressive media, stainless steel lined with PTFE is available, offering excellent corrosion resistance at temperatures up to 200°C.

Process Conditions:

The ISEN-UHC series is built to withstand demanding industrial environments:

- High Temperature and Pressure: These gauges can handle fluid temperatures ranging from -40°C up to 450°C and working pressures up to 16MPa.

- Fluid Characteristics: They are suitable for a wide range of fluid densities, with a minimum requirement of ≥0.45g/cm³ for most models, and can accommodate fluid viscosities up to ≤14 m/s.

Advanced Monitoring and Control

For modern process automation, the Valvelink Bypass Level Gauge can be integrated with sophisticated monitoring and control systems.

- Transmitter Outputs: Gauges can be equipped with a level transmitter to provide a continuous 4-20mA current signal, with options for RS485 and HART communication protocols. The resolution of these transmitters is selectable, with options of 5mm, 10mm, or 20mm.

- Switching Capabilities: For control purposes, the gauges can be fitted with multiple reed tube switches. These switches are available in normally open (NO), normally close (NC), or SPDT types.

- Remote Indication: When matched with a secondary indicator, remote level monitoring can be achieved.

Specialized Models for Demanding Applications

Valvelink also offers specialized Bypass Level Gauge models for unique and challenging applications:

- High Viscosity Liquids: The ISEN-UHC-V side-top mounted model is specifically designed for heavy oil, crude oil, and resin, accommodating medium viscosities of 1.5 Pa·s or less.

- Vaporizing Fluids: The ISEN-UHC-T top-mounted gauge is ideal for liquids that easily vaporize, such as LPG and methane, and is widely used in LPG stations. This model features titanium floats and is suitable for working temperatures from -80°C to 80°C.

For a reliable, accurate, and versatile liquid level monitoring solution, trust the ISEN-UHC series Bypass Level Gauge from Valvelink. Our commitment to quality and customization ensures that you receive a product tailored to your specific operational needs. Contact us today to discuss your application with our team of experts.